coriolis flow meter troubleshooting

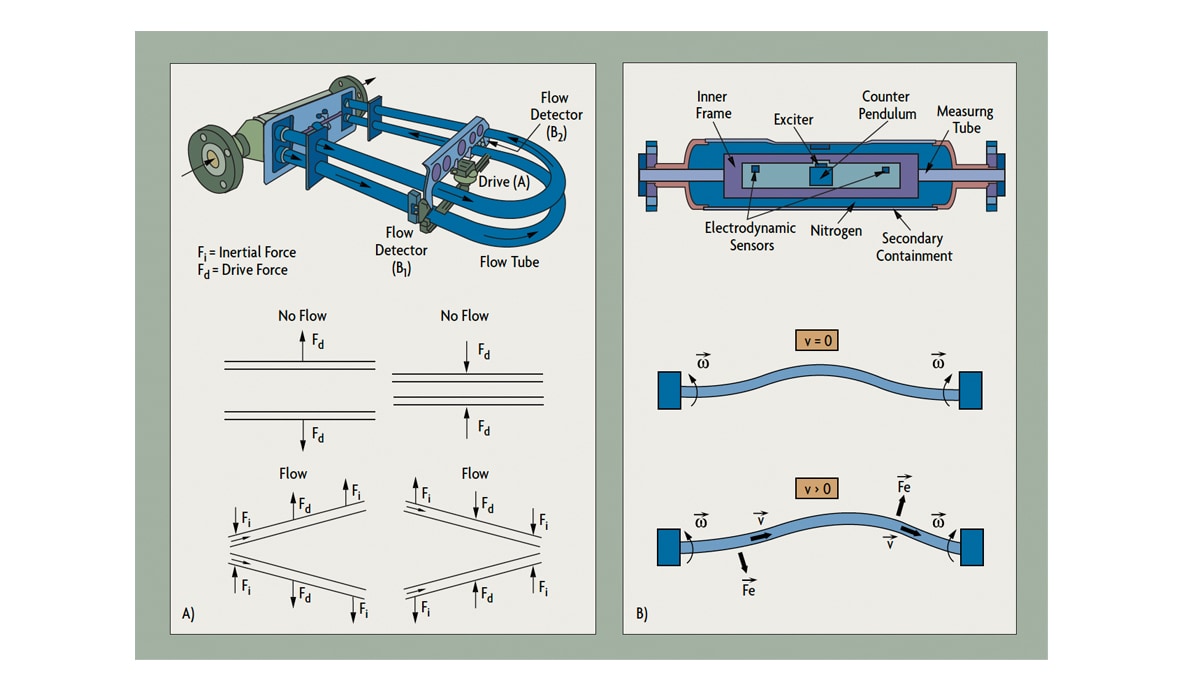

Available in single and dual 100 Watt models and a 240 Watt 10 Amp model. The meter directly measures the mass flow rate of a fluid by vibrating driving a fluid-conveying tube at resonance.

What Is A Coriolis Flow Meter And How Does It Work

2 check for leaks around the flow meter inlet and outlet connections.

. These guidelines are designed to aid in troubleshooting and operation of provers that are in use together with Micro Motion Coriolis meters. And they can be stable over a long period of time. Zhejiang Sealand Technology Co Ltd.

Were commitment to offer you the competitive price remarkable products excellent also as fast delivery for Coriolis Mass Flow Meter Troubleshooting Coriolis Flow Meter Troubleshooting Coriolis Meter Troubleshooting We warmly welcome you to come to visit us personally. I am looking for ideas on how to minimize the fluctations in the readings. The transmitter must be earthed unless special protection measures have been taken eg.

Learn about the methodology for troubleshooting coriolis flowmeters by. No operator shall be permitted to perform procedures relating to installation. This is causing the density and hence the flowrate to be erratic.

What can I do for you. The problem is reportedly related to the meter drive coil running out of energy. Troubleshooting information can be found in the configuration manual.

This additional solubility can help prevent evolution of bubbles in pumps valves and other piping components. SolaHD IP67 SCP-X power supplies mount directly on the machine or production line deliver reliable distributed and remote field power to machine controls. Coriolis Flow Meter Troubleshooting If no leaks are present bring the system up to the operating pressure.

Coriolis Flow Meter Troubleshooting 10 out of 10 based on 304 ratings. Any drive gain value below 100 means that the flow tube vibration in the Coriolis meter is still at the precise target amplitude distance apart at the peak of cycle. Coriolis flow meter troubleshooting.

Our problem is we have air bubbles entrained in the liquid. 1 When using coriolis mass flow meters to measure liquids flow with entrained air especially viscous liquids the meter reports inaccurate readings. It allows for measuring various fluids eg.

However by creating back pressure of 40 psig in the piping the water can retain additional gases in solution up to about 14 by volume. At room temperature water can dissolve only about 2 by volume at atmospheric pressure. Flow Measurement Metering Research Flow Measurement Services Flow Measurement Research Programs Flow Meter Calibration Services Flow Test Systems Flow Calibration Capabilities.

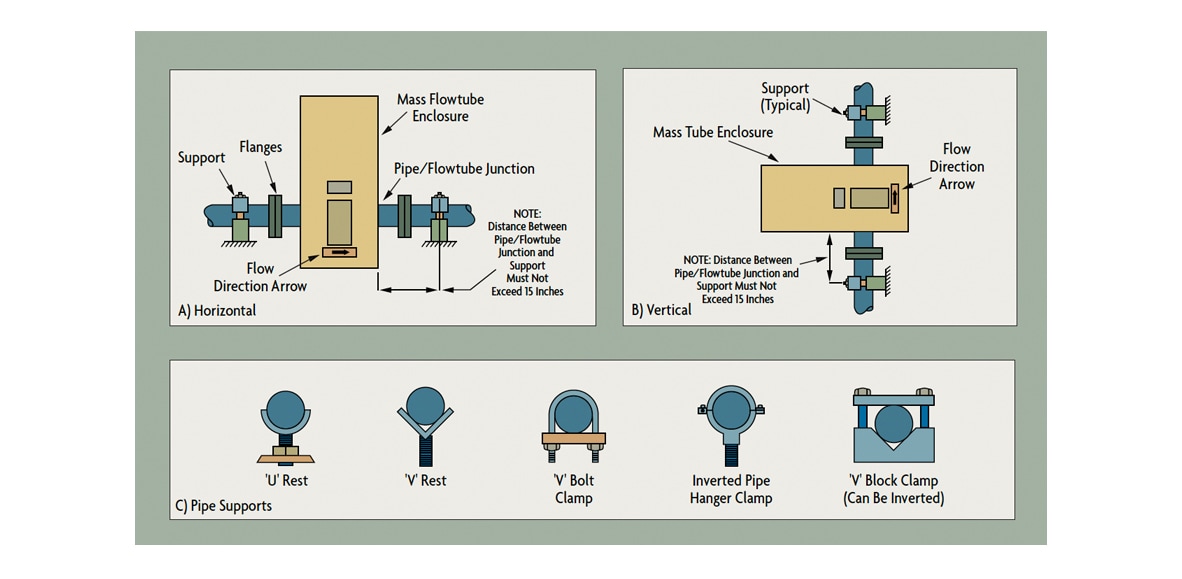

PELV Protective Extra Low Voltage. A common geometry for high-performance Coriolis flow meters is the dual U tube shown in Figure 1. A special LED indicator is provided for indication of some faults of the coriolis mass flow controller.

Coriolis meters are multivariable devices that directly measure mass density and temperature. These parameters are evaluated after the flow meter installation to determine its performance status and as part of a. When choosing a flow meter for any application some performance parameters are more critical than others to determining which meter will work best in an application.

Micro Motion ELITE flow meters are high- precision Coriolis flow meters that are often used in the oil and gas industry in conjunction with volume provers. This means you can trust the mass flow measurement as long as the drive gain is any number less than 100. Entrained air requires additional energy to drive the meter tube as the entrained air absorbs some of the energy.

The flow enters from the pipeline and is split by the inlet manifold into the two U-shaped flow tubes. SolaHD SCP-X Series Standalone IP67 Power Supplies. We have installed a Coriolis mass flow meter on a 2 process line.

But Coriolis meters are not. Three primary parameters include in order. China Coriolis Mass Flow Meter Troubleshooting Manufacture Choose the High Quality Coriolis Mass Flow Meter Troubleshooting From China.

Troubleshooting Possible faults their probable cause and solutions are presented in Table 28. The Unit has been calibrated and is operational. Return policy Follow Micro Motion procedures when returning equipment.

Accuracy linearity and repeatability. Motion Inc explored recent advancements in Coriolis meter diagnostics. If none of the troubleshooting questions or.

These oscillations are recorded by sensors fitted at the inlet and outlet of each tube. The installer must ensure that the measuring system is correctly wired in accordance with the wiring diagrams. As an industry leader in Coriolis meter research testing and systems SwRI provides Coriolis flow meter troubleshooting services to clients around the world.

Dear ERIC ive got a probleme with a coriolis flowmeter is from krohne optimass 3000 F 25S when there is no flow it gives 0 but suddenly it gives negative values till -1000 Lh and if the velocity is too low the Flowmeter PV pumps between 700 and - 2000Lh and can not reach the SP the range is 0-20000Lh thanks for your advices. The recent application of Coriolis flowmeters in an innovative and patented Air Products and Chemicals process has greatly improved the ability to maintain efficient operation despite a common and longstanding hardship Fig. Also all of our workers are experienced in printing field for Coriolis Flow Meter Troubleshooting Coriolis Mass Flow Meter Troubleshooting Coriolis Meter Troubleshooting Look forward to the future we will focus more on the brand building and promotion.

LED is located above the display and its color and blink period indicates the coriolis controllers fault shown in Table 29. Zhejiang Sealand Technology Co Ltd. This is due to the fact that detection is based on volume and the bubbles are mistaken for fluid.

The meter will still function above 100 but this indication means. They dont have moving parts. IRREGULARITY OR DEVIATION IN FLOWS.

Since Coriolis type flow meters measure mass flow they are unaffected by air bubbles. For electromagnetic type flow meters bubbles can cause unstable flow readings. Galvanically isolated power supply SELV or PELV SELV Save Extra Low Voltage.

They dont require straight runs of pipe or flow conditioners. If you still feel abnormal after the above work is completed you should check whether the working parameters set in the transmitter are correct. Method to perform zero flow calibration again.

Proving results may vary if unstable.

How To Verify And Test A Coriolis Mass Flow Meter Tactical Flow Meter

How To Zero A Coriolis Meter Using The 5700 Transmitter Display And Prolink Youtube

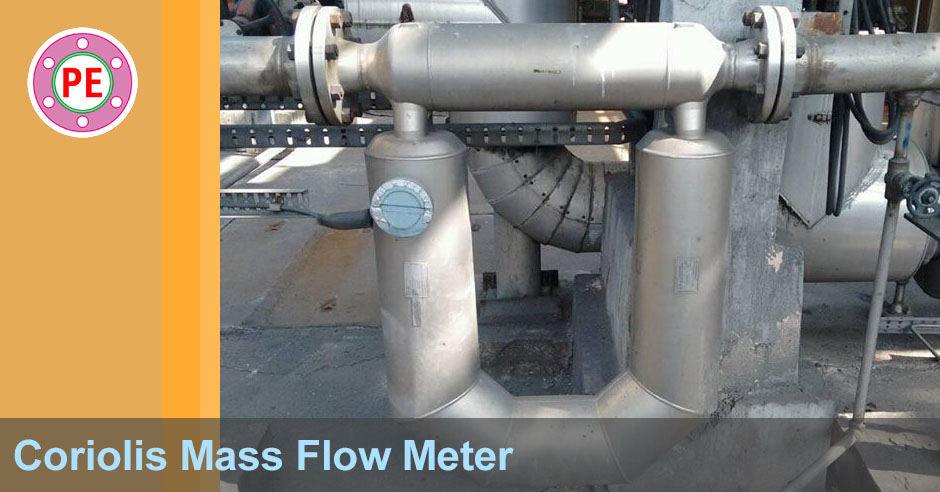

Coriolis Mass Flow Meter The Piping Engineering World

The Basics Of Flow Measurement With Coriolis Meters Part 2

How To Install A Coriolis Flow Meter

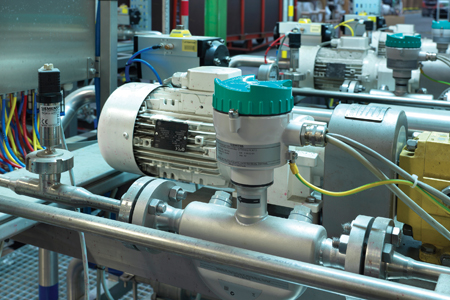

Endress Hauser Industry Optimized Coriolis Mass Flow Transmitter From Endress Hauser Automation World

Enhanced Online Diagnostics For Coriolis Mass Flowmeters Krohne Youtube

The Basics Of Flow Measurement With Coriolis Meters Part 1

:quality(90)/images.vogel.de/vogelonline/bdb/1565700/1565739/original.jpg)

New 2 Wire Coriolis Flow Meters

Industrial Instrumentation The Working Principle Of Coriolis Flowmeters Electronic Engineering Engineering Technology

Proline Promass H 100 Coriolis Flowmeter Endress Hauser

3 Dirty Little Secrets About Coriolis Flow Meters

Mass Flowmeter Coriolis Supplier Manufacturer Mass Flowmeter Coriolis Manufacturer Supplier Flow Measurement Flowmeter Supplier Abb

Coriolis Mass Flow Meter The Piping Engineering World

What Is A Coriolis Flow Meter And How Does It Work

Krohne Optimass 7400 Coriolis Mass Flowmeter Control Specialties

How To Verify And Test A Coriolis Mass Flow Meter Tactical Flow Meter